- +66 34-406-549

- info@zip1993.co.th

- Mon - Sat : 8:00 - 17:00

Quality Control

Quality control

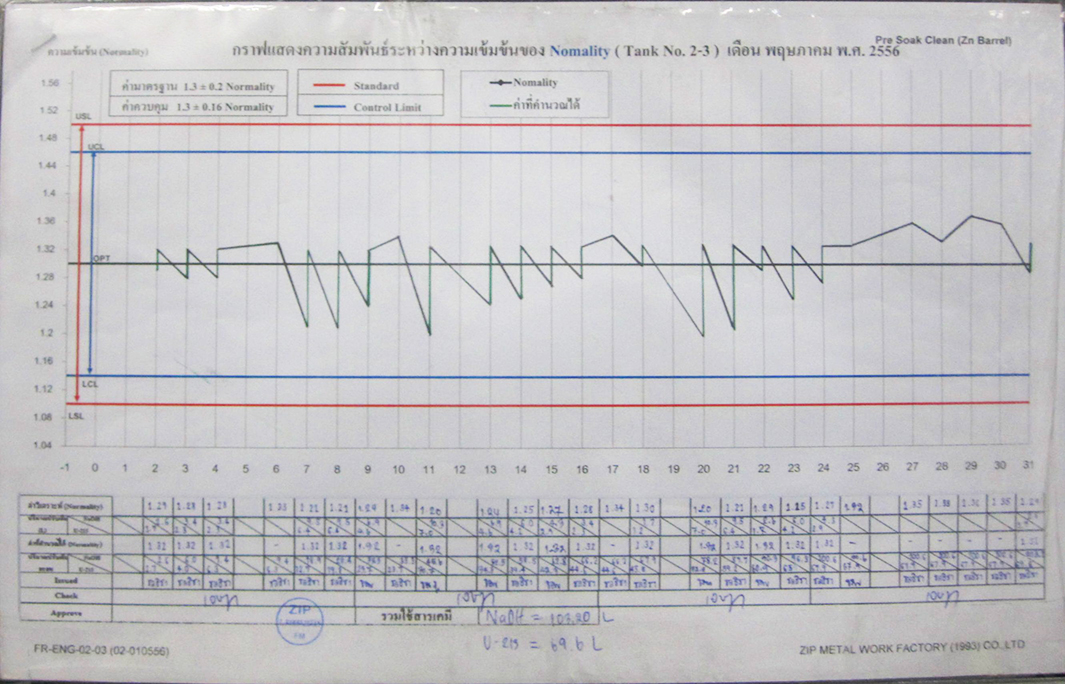

Zip Metal Work (1993) Company Limited is dedicated to developing and guaranteeing the quality of customer product. In order to meet the standard from customers, the company has inspected, measured, analyzed and controlled quality with a variety of tools. In order for customers to receive the highest quality products And has received ISO9001 quality system certification to meet customer needs.

Analysis equipment

Sorting test

The team designed the inspection. Starting with the process of experimenting with customers. By inspecting the product according to detailed steps To ensure that the products will be delivered to customers. Guaranteed to be of the highest quality. To respond to customer needs

Inspection staff must be trained and tested to be able to inspect work for customers.