Characteristics of Zinc Plating with Alkaline Zinc Advantages

- Zinc plating is a well-suited tool for protecting iron and steel products from corrosion. A metallurgical bond between zinc and steel allows zinc to corrode preferentially and thus protect the iron or steel against rusting.

The basic principle behind electroplating is the process of depositing a metal layer on a metal base using a direct current through an electrolyte solution. Zinc is one of the easiest metals to plate, giving good corrosion protection without using exotic chemicals. The finish can be polished to give a shiny luster almost as good as chromium. - Furthermore, zinc electroplating provides smoother, brighter surface in a shorter time than hot-dip galvanization in which steel parts are processed submerged in a bath of molten zinc. Alkaline zinc option produces a reliable, consistent coverage compared to acid zinc, with good brightness.

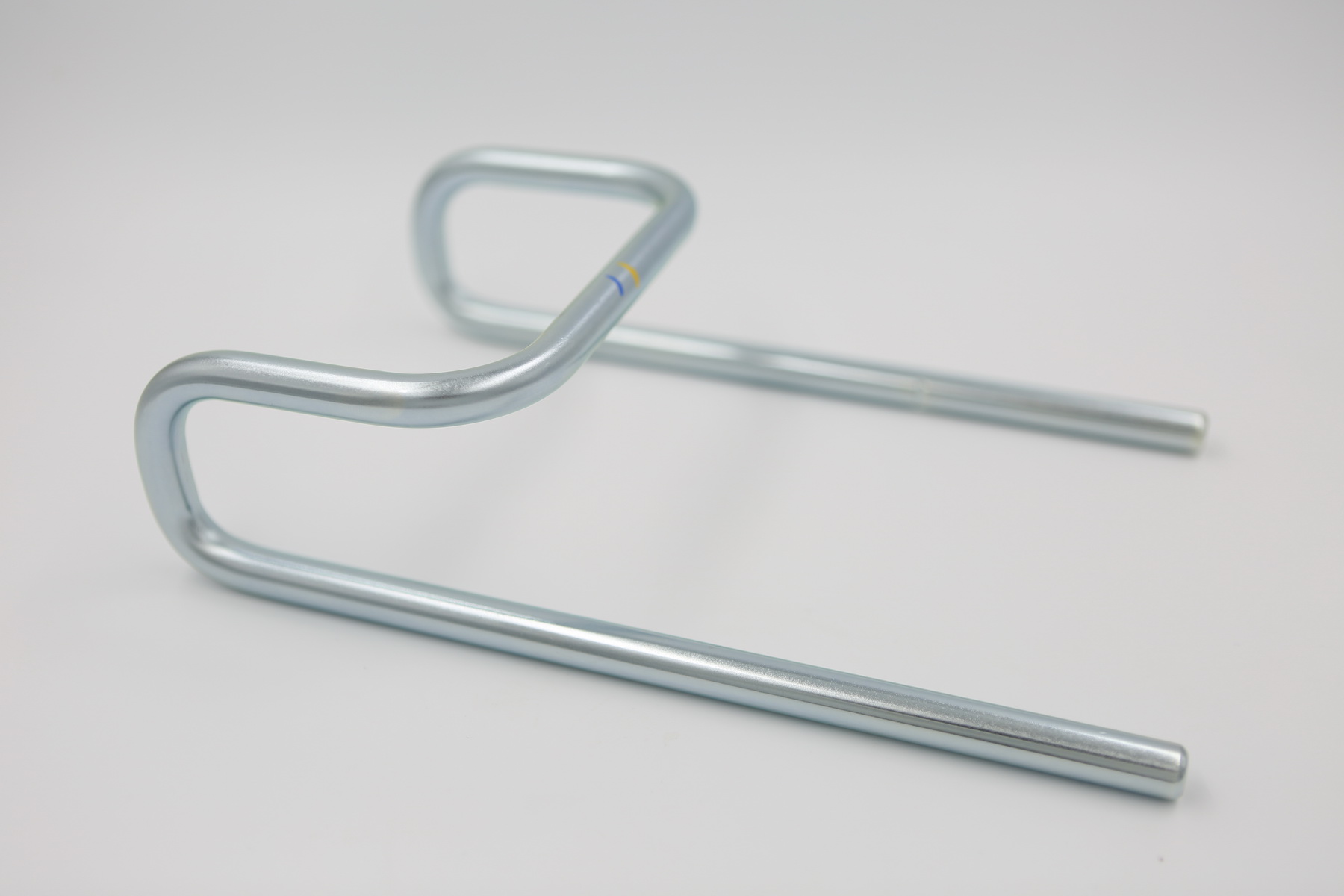

- Zinc plating is extensively used by the automotive industry and for military applications. It is applied mainly to steel, but applicable to aluminum, copper, or brass with special pre-treatment. Colors are usually offered in clear (white), rainbow, green or black according to the type of post-plating treatments.

- At ZIP Metal Works, we offer compact automatic/automatic barrel plated, alkaline zinc, beautifully and consistently, specializing in steel products.