Quality Control

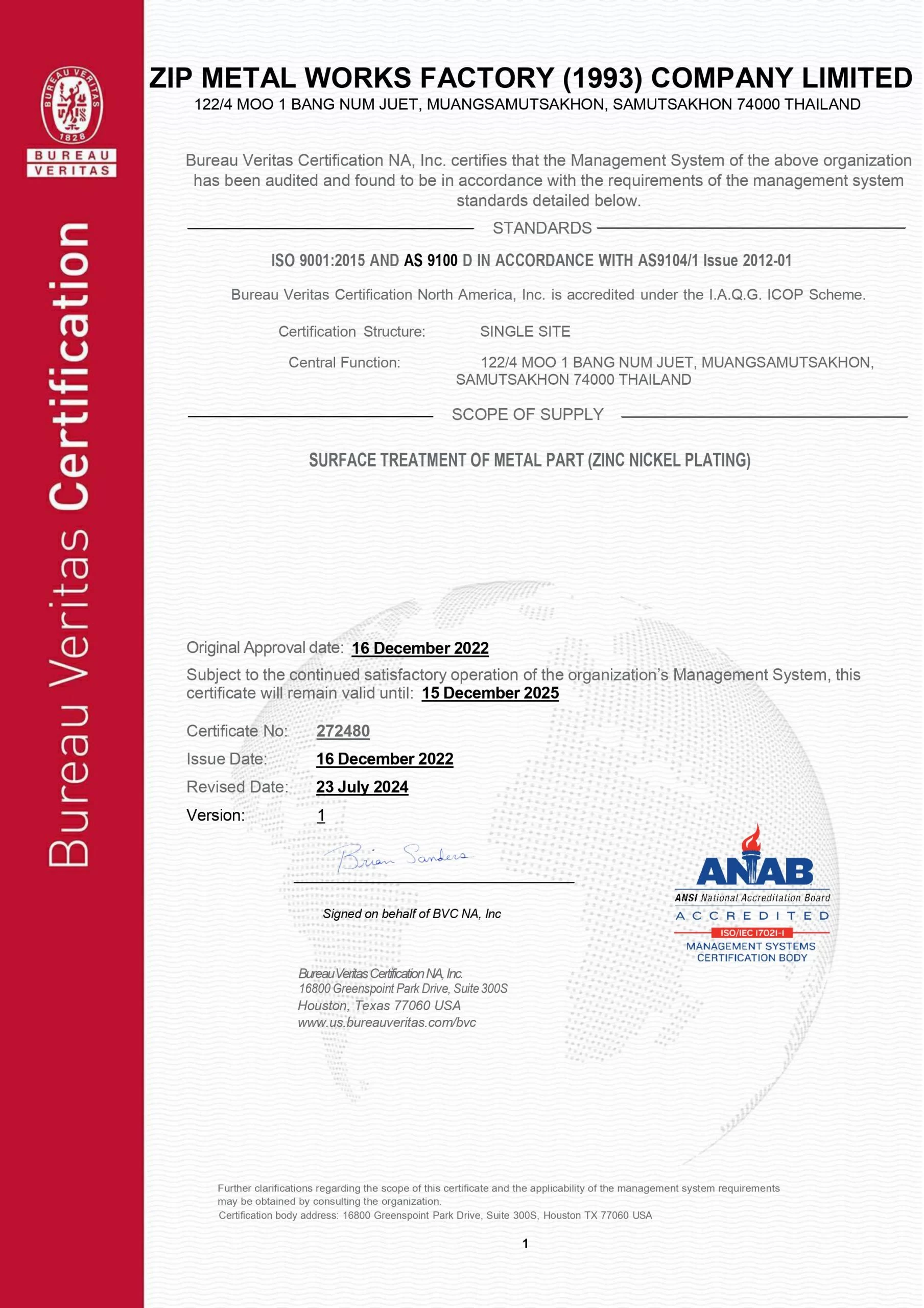

Zip Metal Work (1993) Company Limited is dedicated to developing and guaranteeing the quality of customer product. In order to meet the standard from customers, the company has inspected, measured, analyzed and controlled quality with a variety of tools. In order for customers to receive the highest quality products And has received ISO9001 quality system certification to meet customer needs.

Analysis Control

Chemical analysis and control from the LAB room

Analysis Equipments

Salt Spray Test Chamber (Corrosion Testing Chamber using Salt Spray)

An X-ray instrument used for measuring coating thickness, specifically for surface plating or coating layers, commonly utilized in the metal plating and electronics industries.

The AAS instrument is essential for maintaining plating bath quality, providing accurate measurement of bath composition and contaminants, ensuring consistently high-quality plating results.

A micrometer is a high-precision measuring instrument, and Mitutoyo is a well-known brand recognized for its accuracy and reliability in dimensional measurement.

A spectrocolorimeter is a high-precision instrument used to measure and analyze color consistency according to international standards, making it essential for industries requiring strict color quality control.

A UV-Vis Spectrometer provides information about the electronic structure of molecules and offers high accuracy in measuring the concentration of colored solutions or substances that can react to produce color.

A Creep Rupture Testing Machine is an instrument used to determine the deformation behavior and fracture of materials under constant stress/load and constant elevated temperature conditions above room temperature.

An eddy current coating thickness gauge is used to measure the coating thickness on non-ferrous (non-iron) materials.

Sorting Test

- The inspection design begins with collaborative testing with the customer, followed by detailed procedural inspections to ensure that products delivered to customers are of the highest quality, meeting their requirements.

- Inspectors must be trained and passed tests before they can perform inspections for customers.

Zip Metal Works Factory 1993

Zip Metal Works Factory 1993 122/4 Moo 1 Bangnamchued Meung Samutsakorn Samutsakorn 74000

Contact us

saleniti@zip1993.co.th

Our Service

News & Articles

Contact Us

Terms of Service

Privacy Policy